FIRST Robotics is an amazing program. Over the 4 years as team president, our team built 3 robots all of which I am so proud of, and of which I learned so much about building things, leading a team and working hard.

Slow beginnings. Starting a robotics team is a hard technical, financial, and organizational issue, especially when you are from a small town who's track record is not great for STEM (Science, Technology, Engineering and Maths) in high schools. However, we raised the funds, built a bot, and competed.

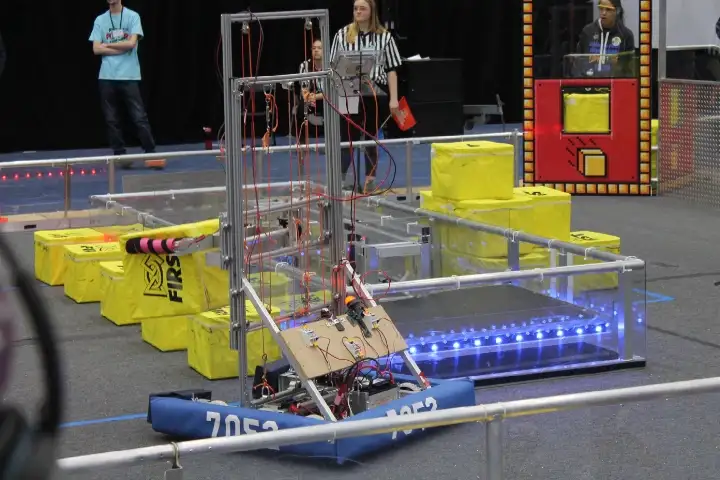

The game this year (or at least what we focused on) was to pick up milk crates, lift them, and shoot them out. The overall deign of our robot was a set of elastically tensioned arms with motorized wheels which can spin to receive crates, and spin out to shoot them out. This system as mounted on an elevator lift (cascading) which could move the crates up after being received. This was not all smooth sailing though. In our first competition (out of two) we did not have the front arms finished, so we improvised by using a threaded rod we found at home depot, connected it to a motor, and put two pieces of aluminum bar to make defector arms. as seen below with a pink pool noodle taped around it.

In our first year, we didn't organize how we would ship the robot either, which meant we ended up taking apart the robot days before both competitions, fit it inside two suitcases, and brought it on the plane. From there, we had to put together the robot at the competitions we competed at, with limited build time. This earned out team the nickname the "suitcase team." below is a picture of a near complete rebuild at our second competition.

Overall, our performances were subpar at best, but I knew that it was only our first year. I learned that running a team is so much more than just building the robot. I also took away the fact that I loved building things in a team, and was determined to make our second year count.

Getting up to speed. This year was about redemption, and taking the lessons from the previous year to make a robot that could compete, and not simply exist. The game this year was to pick up and deposit large balls, and frisbee like disks called hatches. As well, the ability to climb a large platform. Initially we focused on the hatches, but we ended up accomplishing all three tasks this year. As a team, we came up with an idea for an arm which could pick up the hatches, by driving up to them, sticking its hand through and pulling them off; Something like this design.

So, we starting building this system. We utilized my CNC router, and my new 3D printer for manufacturing, along with the schools welding shop. We started building this system, and subsequently tested it.

We did some testing....

And then got the system working!

At this point, we had more work to do at refining this system to make it more consistent and reliable. However, this meant we had time to start working on other areas of the robot. While most of the team worked on improving our arm, I spent our remaining build time to build a climber for the robot, which could climb up a large ledge. The idea I came up with was to have an arm at the front which lifted from the ledge, and a leg at the back (using a gear rack) which stood the robot up. The video below is the proudest system I have built in my FIRST Robotics career.

Competition this year went better, on account of a better scoring system robot. However due to some programming issues which were created the night before our competition, we were not able to climb during the competition, losing us many points, and making us unviable for the play-offs . Still though, I am very proud of this robot.

While this was the proudest I have been about a robot, leading the team without our cofounder, Our expectations were cut short after competitions were cancelled due to covid. The goal this year was to collect and shoot balls into holes in a wall, and have the robot do a "pull-up." While we don't have much media following the design process, as we as a team were not smart enough to document our work, these two videos show the two major subsystems of the robot, both of which were lead in the design and build by myself.

Sadly, with no hope for competition, and the next year being virtual due to covid, the team decided to disband, a rather sad ending to what was my favourite high school experience. This year I learned a lot more about rapid iteration, and building things fast, while still making them work. I also learned how much harder it was to lead a team alone, and not have a co-lead help me.